Electronic Waste (E – Waste)

Introduction: E-waste is a popular name for electrical and electronic equipment (EEE) discarded after their end of life. Discarded laptops, desktops, cellphones and their batteries,.air conditioners and television sets, cables, and wires , tube lights and CFLs which contain mercury , are some examples of e waste . It is one of the fastest growing waste streams in the world. E-waste is an Urban Mine as it contains several precious , critical and other non critical metals that, if recycled , can be used as secondary materials.

E waste can be classified under three major heads :

- White goods: Household appliances

- Brown goods: TVs, camcorders, cameras and

- Grey goods: Computers, printers ,fax machines , scanners etc

Waste from white and brown goods are less toxic when compared to grey goods. Grey goods contain lead, cadmium, mercury, chromium etc. which can be dangerous for both environment and health.

Global annual E waste : Global E-waste monitor (published by UN university) estimates that 53.6 million tonnes(7.3 kg per capita) of e-waste was generated world over in 2019. This is an increase of 21% in just five years. This is expected to go to 74.7 Mt by 2030.

Asia generated the greatest volume -some 24.9 Mt followed by Americas and Europe.

Very less recycling : Only 17.4% of e waste generated in 2019 was collected and recycled.

Number of countries which have adopted a national e-waste policy ,legislation, or regulation has increased to 78. India is the third-largest e-waste generator in the world after China and the USA (Global E-waste Monitor 2020). E waste generation in India is expected to grow rapidly in the coming future (income, urbanisation, changing technology , import(legal or illegal) , poor quality equipment , power surge issues etc)

The value of raw materials in the global e–waste generated in 2019 is equal to approximately $ 57 billion USD. Nearly 82% of e waste is generated by households,the rest by corporate and government institutions.

Harmful effects of E-Waste :

- E–waste are repositories of hazardous and toxic heavy metals like mercury,cadmium,chromium,halogenated substances etc.

- Refrigerators, Acs, etc contain potentially harmful substances such as CFCs and HCFCs which may lead to Ozone depletion and climate change..

- Unscientific extraction of these metals lead to heavy air pollution, water pollution and soil pollution through burning, leaching etc.

Health Impacts: Metal such as lead, mercury and cadmium can cause damage to the central and peripheral nervous systems, affect brain development of children and cause damage to the circulatory system, kidneys and reproductive system.

According to WHO, 18 million kids from low and middle income countries working at e -waste dumpsites face the threat of health hazards. This was informed through a new report titled children and digital dumpsites which was published in June 2021

E-Waste in India:

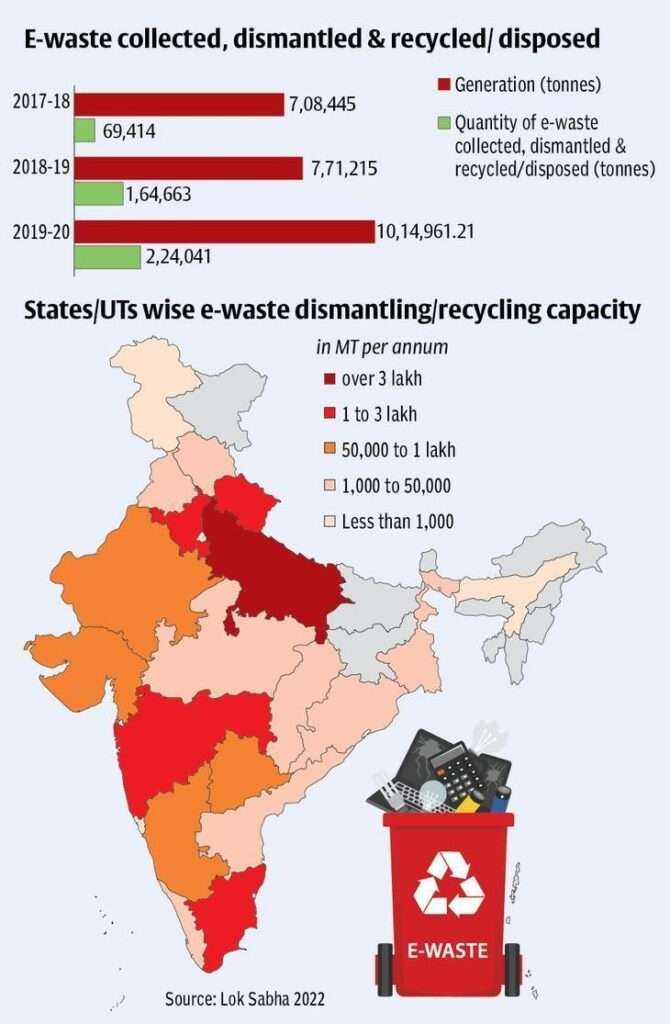

- Only 22.7 per cent of the e-wasteout of the total 10, 14,961.21 tonnes generated in 2019-20 in India was collected, dismantled, and recycled or disposed off.

- This e-waste is composed of 21 types of electrical and electronic equipment (EEE) notified Under the E-Waste (Management) Rules, 2016.

- India is the world’s third largest generator of e-waste after China and the US, according to the UN Global E-Waste Monitor Report.

Maharashtra generates the most e-waste among all the Indian states.

Uttar Pradesh, Uttarakhand, Tamil Nadu, and Haryana are among the States that have a bigger capacity to dismantle and recycle e-waste.

E-waste typically does not feature in the list of municipal solid waste and therefore it is not a direct mandate for the cities to collect, transport, and manage them.

E-Waste Management in India:

Laws to manage e-waste have been in place in India since 2011, mandating that only authorised dismantlers and recyclers collect e-waste. E-waste (Management) Rules, 2016 was enacted in 2017.

India’s first e-waste clinic for segregating, processing and disposal of waste from household and commercial units has been set-up in Bhopal, Madhya Pradesh.

Originally, the Basel Convention (1992) did not mention e-waste but later it addressed the issues of e-waste in 2006 (COP8).

The Nairobi Declaration was adopted at COP9 of the Basel Convention on the Control of the Trans-boundary Movement of Hazardous Waste. It aimed at creating innovative solutions for the environmentally sound management of electronic wastes.

E – Waste Management Rules, 2016:

In march 2016, Ministry of Environment , forest and climate change has notified the E waste management rules 2016 in supersession of the e- waste (management and handling ) rules , 2011 E waste would now include CFL and other mercury containing lamps as well as other such equipment .

Extended producer responsibility For the first time, the rules have brought the producer under EPR with targets. The amended targets (march 2018) include recovery of 10% of waste generated by 2017-18 which increases by 10% every year to reach 70% 2023 onwards.

Deposit Refund Scheme has been introduced as an additional economic instrument wherein the producer charges an additional amount as a deposit at the time of sale of the electrical and electronic equipment and returns it to the consumer along with interest when the end-of-life electrical and electronic equipment is returned.

Various producers can have a separate producer responsibility organisation (PRO) and ensure collection of e waste as well as disposal in an environmentally sound manner.

Production of hazardous substances –> cost of sampling and testing would be borne by the government. But if a product doesn’t comply with Restriction of Hazardous Substances (RoHS), the cost would be borne by the producers. (2018 amendment)

Role of state governments has been introduced to ensure safety, health and skill development of workers involved in dismantling and recycling operations. Process of dismantling and recycling has been simplified through one system of authorization (CPCB) throughout the country.

E-waste management rules 2022 :

The government recently notified E-waste (management) rules 2022 that will come into force from 1 April 2023.

Application: It will apply to every manufacturer, producer, refurbisher, dismantler and recycler involved in manufacturing, sale, transfer, purchase, refurbishing, dismantling, recycling and processing of e-waste or electrical and electronic equipment.

The rule is applicable to all electrical devices and radiotherapy equipment, nuclear medicine equipment and accessories, Magnetic Resonance Imaging (MRI), electric toys, air conditioners, microwaves, tablets, washing machine, refrigerator and iPad among others.

Restrictions: The government has restricted the use of hazardous substances in manufacturing electrical and electronic equipment (EEE) following deaths due to exposure to radioactive material.

It mandates the reduction of the use of lead, mercury, cadmium among others in the manufacturing of electronic equipment.

Reuse and recycling : Manufacturers shall use the technology or methods so as to make the end product recyclable and shall ensure that components or parts made by different manufacturers are compatible with each other so as to reduce the quantity of e-waste.

Strict monitoring : The Central Pollution Control Board shall conduct random sampling of electrical and electronic equipment placed on the market to monitor and verify the compliance of reduction of hazardous substances provisions.

If a product does not comply with the e-waste management rules, the manufacturer will have to withdraw all samples from the market.

Extended Producer Responsibility Certificates: Draft rules aim to incentivise registered electronic waste recyclers by introducing EPR or Extended Producer Responsibility certificates (which was not part of 2016 Rules).

E-waste exchange facilities: The EPR requires producers to set up e-waste exchange facilities to facilitate collection and recycling, and assign specific responsibility to bulk consumers of electronic products for safe disposal.

Imports : Imports or placement in the market for new electrical and electronic equipment shall be permitted only for those which are compliant with provisions laid down by the government.

Disposal: It is the responsibility of the manufacturer to collect e-waste generated during manufacture and to ensure its recycling or disposal. However, the rule does not apply to waste batteries, packaging plastics, micro enterprises and radio-active waste, as covered under the provisions of the law.

The notification does away with PRO and dismantlers and vests all responsibility of recycling with authorised recyclers, only a handful of whom exist in India. Now, Authorised Recyclers will source a quantity of waste, recycle them and generate electronic certificates. Companies can buy these certificates equivalent to their annual committed target and thus do not have to be involved with engaging PROs and dismantlers.

Construction and Demolition waste : India’s record in dealing with construction waste is very poor. Until 2016, it was covered under the municipal waste management rules only. Further, there were no state laws to deal with it.

In 2016, the government for the first time came up with construction and demolition waste management rules,2016. These rules are aimed at promoting recovery, recycling and reuse of the waste generated through C&D.

Mandatory segregation of C&D waste into four types – concrete , soil, steel and wood, plastics, bricks and mortars. Deposit it at collection centres or hand it over to processing facilities. It makes all stakeholders responsible for waste disposal (be it small scale generators, the municipal body or the government) Land department – provide land for storage, processing and recycling of C&D waste. It makes debris recycling mandatory. Illegalizes the dumping of waste outside designated areas. Waste processing authorities –> should have authorization from SPCB and should be located far away from habitation.